GAS GLASS PRIMER

“GAS Glass Primer.” is a device that improves the hydrophilicity and adhesive strength of objects. A special flame makes the surface hydrophilic instantly, improving the quality of painting, adhesion and printing, as well as productivity. Since the process takes such a short time, adverse effects of heat and flame are small, meaning it can be used for a wide variety of substrates and usages.

USABLE FOR A VARIETY OF APPLICATIONS AND MATERIALS

Quality and Productivity Improvement:

Instantaneously improves paint application, printing ink, adhesive strength of glues or other adhesives, hydrophilicity, and coating smoothness. This makes it possible adopt new materials or substitute general-purpose paints and adhesives, improving quality and productivity.

Useful for a Variety of Applications and Materials:

Can be used on a variety of materials including metal, glass, plastic (PP, ABS, and more), and silicon rubber. (Note: Effects may vary depending on material. Also, for some materials may be less effective. Please contact us for details.)

No Damage to the Texture of the Substrate:

Unlike scuffing with sandpaper, this treatment does not change surface appearance, texture. Process can be done over a broader area than required, leading to faster and easier processing.

Shorter Delivery:

The next process can start immediately once treatment is done, leading to shorter work time.

Use Anywhere:

Since treatment is done with a hand burner, the size or shape of the object does not matter much. It can be applied to anything from tiny parts to enormous trucks or existing shop windows. Also, it does not use electricity, it can be used anywhere you can use fire.

Eco-Friendly and People-Friendly with No Hazardous Materials:

No organic solvents are used. It can be used at homes or commercial facilities without fear of health damage and a bad smell.

●Principle: Synergy Created Through 2 Effects

The following two actions increases hydrophilicity, adhesive strength, and coating smoothness. These two actions performed simultaneously makes significant improvement in adhesion possible in a short amount of time.

Improving Chemical Bond Strength Through Flame:

Applying high-temperature flames creates oxidation, bringing functional groups to the surface. This increases hydrophilicity, enhancing coating smoothness and adhesive strength.

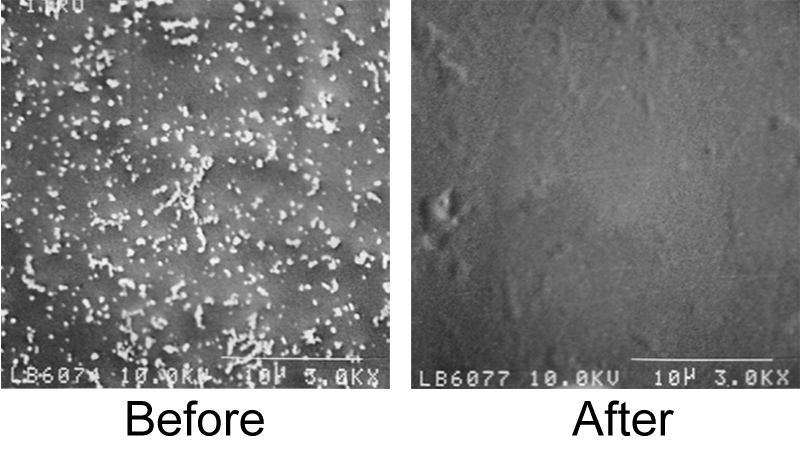

Improvement in Hydrophilicity Through Silicon Oxide Nanoparticles:

The special liquid agent inside the gas cartridge passes through flames and adheres to the surfaces as silicon oxide particles roughly 20 nanometers in size. This creates micro-bumps, which together with the adsorption of silicon oxide, improves hydrophilicity.

USAGE EXAMPLES

Automotive Industry:

Painting metal or resin parts, painting plated parts, pretreatment for coating, adhesion for onboard devices, pretreatment of putty applying, etc.

Manufacturing Industry:

Industrial paint, adhesive, general printing work. In particular built-to-order manufacturing and modeling (prototypes), small-scale production, and manufacturing for short deadlines

Architecture:

Pretreatment for coating of windows, floors, bathtubs, and more, home renovation, etc.